Mechanical and Electrical Engineer. Previously the Engines Engineer of Aero Continente and Cielos Airlines. Currently, Powerplant Senior Engineer of Latam Airlines.

Gives a detailed description of the PW1100G-JM power plant, including engine systems and their components.

The content examines the gear technology that distinguishes the PW1100G-JM engine from traditional turbo fans, as well as the functionality of systems such as fuel and control, air, lubrication, indication, starting, air and exhaust. The training was “hands on”, removing and installing several parts of the engine reviewed in class

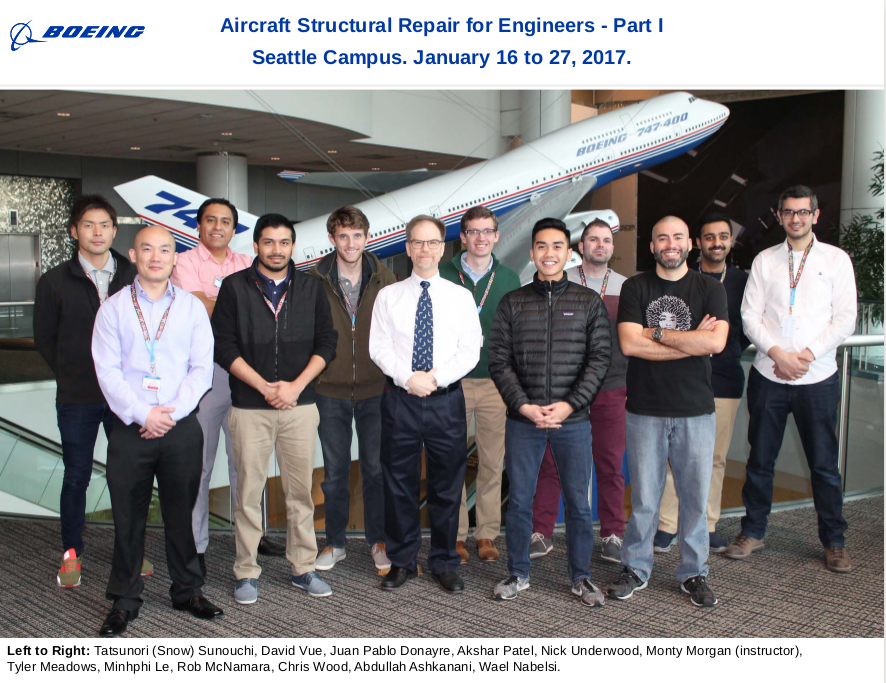

The course teach the repair design philosophy (damage evaluation and design rules), reverse engineering, and repair design for fuselage and wings.

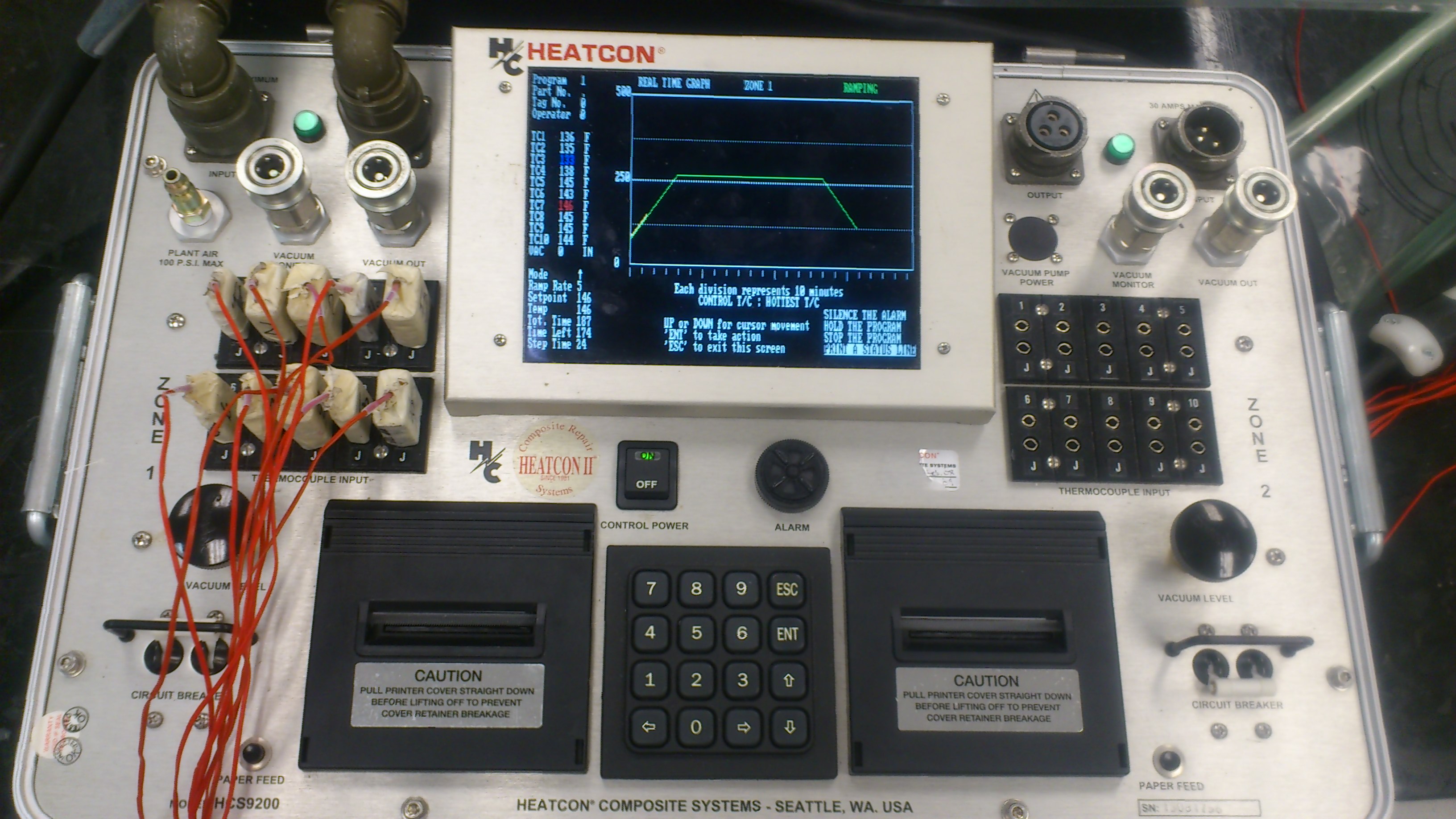

The course is designed to teach how to design repairs to aircraft components made from composite materials (bonded and bolted repairs).  This machine, from our composites shop is the same model used in the trainning.

This machine, from our composites shop is the same model used in the trainning.

Very good course, we acquire a solid base to design Metallic Structural Repairs on Boeing Aircrafts. Very good Team (they are so smart !).

The training included: Installation of transducers and cables, Vibration Survey of CF6-50 turbine engine, real-time measurement, and all the settings required for the ACES Viper II.

In the course we learned the Borescope process (ports, temperatures, cooling procedures, etc), the rules, and the most important, how to assess and measure internal damages.

Was a hands on training, focused in the main sections of the engine like Compressor, Combustion Chamber and Turbine, as well as the Fan drive Gear System and Carbon Seals

This course prepares the student to inspect damage and repairs to 787 solid laminate composite structure using Olympus Omni Scan MX ultrasonic inspection tool (pulse echo and phased array modules).

Below, the kit to perform Service Bulletin 72-1312

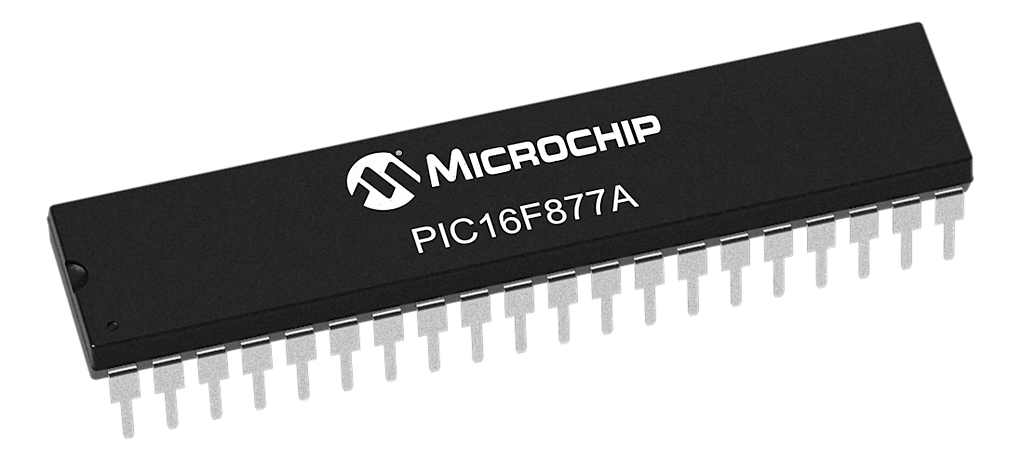

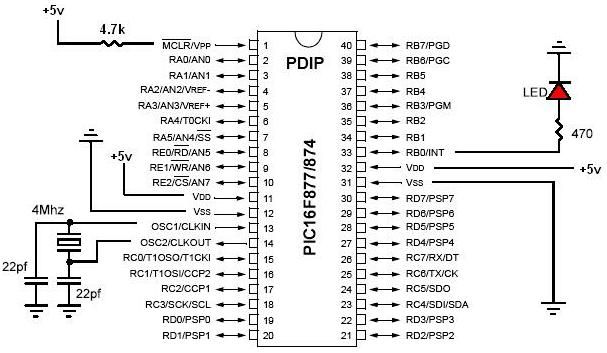

We learned how is the internal logic of a PIC, and how to control it, managing ports (LCDs, usb peripherals).